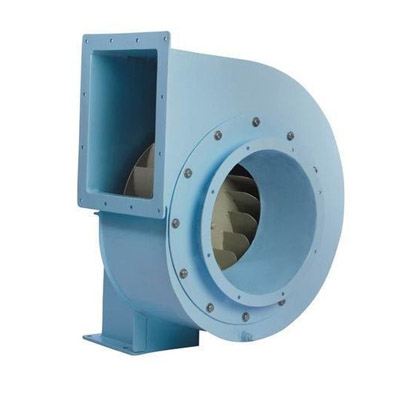

Trusted Blower Fan Manufacturer in Chennai – High-Performance Solutions

Looking for a reliable Blower Fan Manufacturer in Chennai? Safe Enviro System, Chennai offer high-quality, energy-efficient blower fans for industrial and commercial applications. Contact us for customized solutions and competitive pricing!

Safe Enviro System Blower Fans are broadly employed in the market for their top features and nominal costs. Furthermore, in order to provide the best quality of products, these products are checked on varied quality parameters employing the advanced techniques. Safe Enviro Systems products which include tube axial fan, industrial axial fan, induced draft fan, high pressure centrifugal blower fan, industrial induced draft fan and belt drive axial flow fan.